How It's Made

Material Sourcing

The first, and arguably one of the most crucial steps in crafting an Axwell Wallet, is the careful selection of top-tier materials. We believe that the quality of a product is directly proportional to the quality of its raw materials. Axwell wallets are crafted from high-quality materials such as 6061-T6 aluminum, carbon fiber, copper, and 304 stainless steel, carefully chosen for their durability, strength, and aesthetic appeal.

Designing and Cutting

The raw materials are then transformed into the signature slim profile of the Axwell Wallet. High-tech Computer Numerical Control (CNC) machinery ensures precision and consistency, shaping the materials into the necessary dimensions for the wallet's lightweight design.

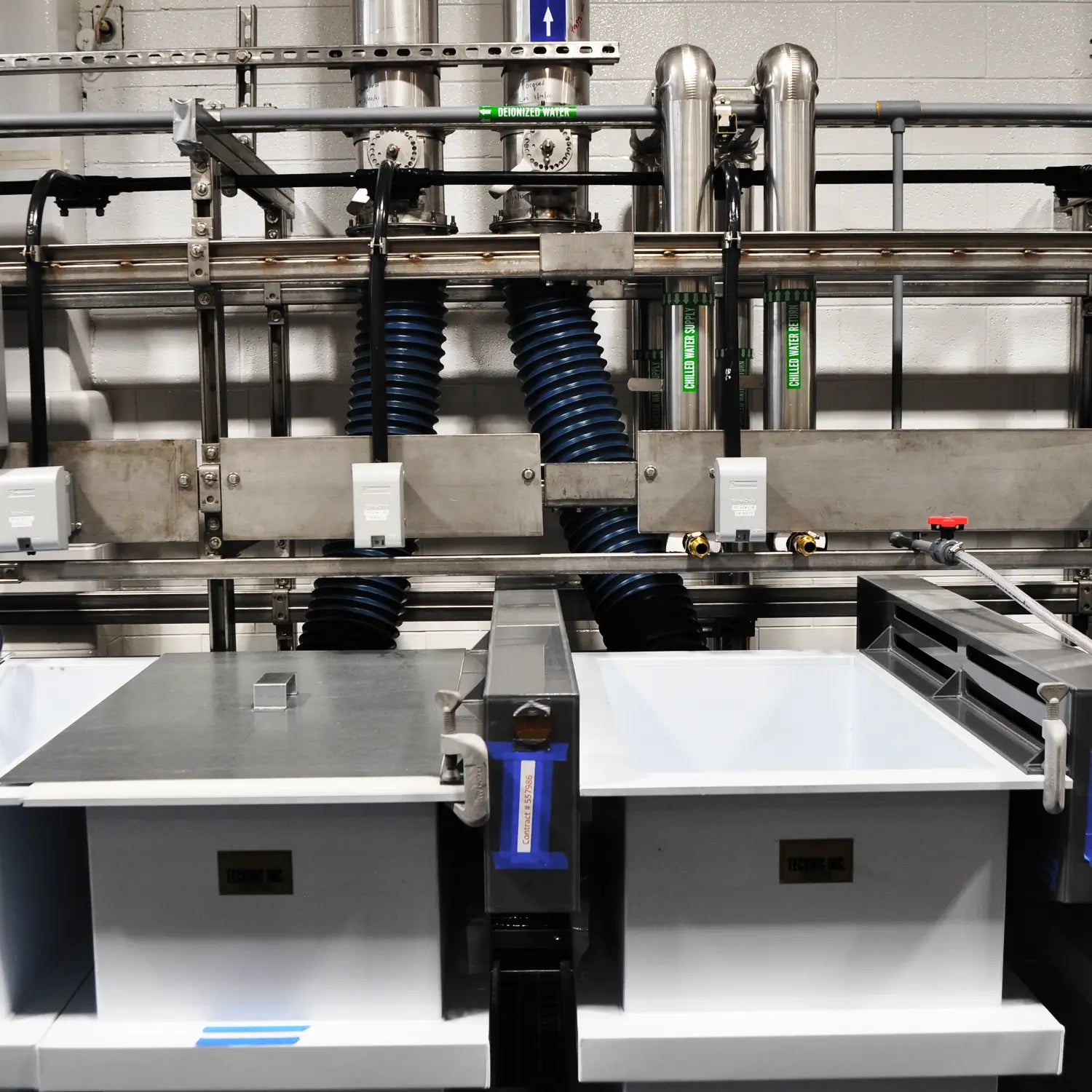

Anodizing Process

To protect the Axwell Wallet from scratches and wear and tear, the wallets undergo an anodizing process. This electrochemical treatment creates a hard, durable surface on the aluminum components, enhancing the wallet's strength and resilience without compromising its lightweight nature.

Embedding Magnets

Every Axwell Wallet is intricately engineered with 24 neodymium magnets, a signature component of our innovative Mag-Lock™ technology that unlocks the potential for customization. Through meticulous positioning, we guarantee that these magnets provide seamless disassembly while simultaneously maintaining a secure hold on all parts, offering our customers a unique blend of customization, convenience, and security.

Final Assembly

Following careful preparation of all elements, we reach the pinnacle of our process - assembly. Each component, from the sturdy shell plates and innovative Mag-Lock™ cover plates, to the robust Tear-Stop™ elastic track, adaptable cash strap and polished money clip, is expertly put together. The outcome is a flawlessly assembled Axwell Wallet, merging seamless functionality with a sophisticated aesthetic.

Quality Control

Post-assembly, every wallet is subjected to a quality assurance process. This procedure confirms that all our creations uphold the stringent Axwell standards in terms of resilience, functionality, and aesthetic design.

Packaging

The final step is packaging. Each Axwell Wallet is carefully packaged with the included cash strap, money clip, sticker, and instructions. The sleek, minimalist design of the packaging mirrors our brand's aesthetic and further enhances the customer's unboxing experience.